|

Introduction

My daughter is learning to play piano and needed a

foot rest to help her be comfortable and maintain good

posture. She is only 5 years old and her feet do not yet touch

the floor when she is sitting at the piano. The foot rest

gives her a place to put her feet and will adjust as she grows.

The footrest has to be adjustable so that we can

lower it as she grows and her legs get longer. It also must

fit over the piano pedals.

Maple seemed like a nice material for my foot

rest. It is a pretty hardwood, and costs a little less than

oak. Any 3/4" lumber can be used for the project.

It can even be built out of plywood.

The foot rest can be painted, but I am using polyurethane.

Materials

I purchased about 8' of 1 x 12 maple. For some

reason, it is not really 1 x 12, but actually 3/4" by about 11

1/4". That works out just fine for this project.

Tip: The piece I bought was not precisely 11

1/4" wide. One end was slightly wider than the

other. If I had cut the pieces the other way, I might have run

into trouble, but because of the order I cut the pieces, everything

worked out fine. Be sure to measure the lumber you buy to make

sure it is the size you intended.

Materials List:

(1) 7' x 12" x 3/4" piece of lumber

(1) box of 1 1/4" wood screws

(10) 3" wood screws

Can of spray polyurethane

Carpenters Wood Glue

(1) Small finishing nail (not shown) |

|

Tools

This project requires basic carpentry tools. Many of the

cuts must be very accurate, so a table saw or radial arm saw is

required. I recently purchased an inexpensive table saw that

was perfectly adequate for the job. The rest of the tools can

be found in most any basement or garage.

|

Tools List:

Table Saw

Drill for drilling holes and driving screws

1/8" drill bit

1/4" drill bit

Pencil

Angle

Measuring tape

Sand paper

Power sander or sanding blocks

Beer ;-)

|

Not shown:

Power Sander

Jig Saw

Nail Punch

|

Cutting the Pieces

The diagram below shows the lumber split into 7 types of pieces labeled

A through G.

Everything can be cut from a single 8' piece of

wood. The following diagram shows how to cut the lumber.

Be sure to cut one piece at a time because this diagram does not

take the width of the saw into account! Measure each piece,

and then cut. Then measure again from the cut edge. A

and B and D and E should be identical. You can use one as the

template for the next. Same goes for the cleats and the

blocks. Use the first as a template to get all the pieces

exactly the same size.

Cutting Order from

one piece of 1x12 maple:

Cutting Steps:

It is hard to work with a piece of wood this long, so the first step

is to cut it in two. Make your first cut about 40" from

the end. This will put you between parts C and D, and give you

two manageable pieces of wood.

Next, cut A, B and C from the 40" piece.

Label the pieces and show which way is up. This is especially

important with A and B because they are almost square.

D and E are next. D will need to slide into the box, so it

should be just a bit smaller than E. If the pieces are not

identical, make the smaller one D.

The cleats (F) should all be exactly the same size.

Fortunately, there is an easy way to do this by using the fence on

your table saw. First, measure 1" off the end of

your lumber, and line it up with the saw blade. Take a small

piece of scrap wood (I used one about 3" wide) and set it just

to the right of your lumber. Then place the fence just to the

right of your scrap wood. Now you can make 10 identical cuts

by pushing your lumber against the scrap wood as shown below:

Cutting cleats on

the table saw:

You can do the same with your blocks (G). Cut

a 2" piece of wood, and use the same setup to cut 1 1/2"

sections from it.

A and B are the two sides of the box. Each has

a cut-out on the bottom which is simply for appearance.

The cut-out should be 1 1/2" high. The legs come off at a

45 degree angle. The two pieces are identical except that they will face each

other. Be sure to mark which side points towards the front on

each. You cannot use the table saw to cut out the legs because

the blade is too big. Use a jig saw instead. The cut

will not be as clean as from the table saw, but sanding will take

out the rough edges and make it look good.

A & B: Left and

Right Side Panels:

C is the back. It has an 8" wide cut-out

for the piano pedals. Make sure that it will fit over the

pedals on your piano! My pedals are about 7 1/2" wide and

2 1/2" high, so I left about an extra half an inch. As

with A and B, you will need to use a jig saw to make the cuts.

The piece is color coded in red throughout all the diagrams. The back holds the entire project

together. The sides and the bottom are attached to the back

with wood screws.

C: Back Panel:

D and E are the adjustable shelf and the bottom

panel. They are the same size, except the bottom has a cut-out

for the pedals. It sits 2 inches off the ground, so it would

otherwise hit my 2 1/2" high pedals. They are colored green and

pink for easy identification in later diagrams. They are both

14 1/2" wide, so that with the two 3/4" sides the width of

the entire unit becomes 16". The 11 1/4" depth will

touch the back, so the whole unit will be 12" deep counting

the width of the back panel.

D & E: Shelf

and Bottom Panel:

F are the ten cleats (five on each side) on which

the shelf slides. They form the five adjustable positions for

the shelf. Each one is 1" wide and 11 1/4" long.

They are attached to the inside of the left and right sides of the

box. Screws and glue hold them on.

F: Cleats (10):

G is the last of the parts. These are four

blocks which are attached to the sides on the very bottom.

They are screwed and glued to the sides and support the weight of

the bottom panel. The panel is screwed to the blocks from the

top to avoid making screw holes on the outside of the

sides. The blocks are 1 1/2" high and 2 inches

deep.

G: Blocks to hold

bottom panel (4):

Drilling Holes

You will need to drill a hole for each screw that

you will be putting in to avoid splitting the wood. You should use a bit smaller than the

screw - probably about 1/8" inch to drill each hole.

Holes for the 1 1/4" screws should be about 1" deep.

For the 3" screws, drill to about 2 1/2". The easiest way

to make sure you don't drill too deep is to wrap a piece of tape

around your drill bit at the deepest point you want the bit to

go. Once the tape touches the wood, you know that you have

gone far enough.

All your screws should be counter sunk to get them

below the surface of the wood. This makes the project look

nicer, makes it easier to sand, and gives you the option of filling

the holes with wood filler to hide the screws . Take a 1/4" drill

bit and drill just a little into each

hole. This will allow you to drive the head of the screw below the surface

of the wood.

Assembly

Side A:

Build each side first. The cleats should be

identical on both sides, and the gap between each set of cleats must

be just a little more than 3/4" to accommodate the width of the

shelf. Use some of the leftover scrap wood to make 10 small

pieces of scrap wood. Lay out all the pieces as shown,

using scraps to represent the position of the bottom panel.

Use a scrap piece and a penny in between each cleat. The penny

makes the gap just wide enough so the shelf will slide easily.

Side view:

The picture below shows the arrangement described

above with the scrap wood and the pennies. Notice that clamps

hold everything together to keep it all from moving while you are

drilling the holes. You can just see the pennies in the

picture.

Cleat and block

arrangement:

Once the cleats are spaced perfectly and clamped, measure and drill the

holes, two in each block and three per cleat. Screw in the

blocks but not the cleats. Take them off, but be sure to keep

them in the same order so you can put them back exactly where they

were before. Now, attach the bottom to side A by drilling

holes and screwing the bottom to the blocks with two screws.

Now, you can attach the cleats.

Side B:

This side is a mirror image of side A. The

only difference is that you do not need to attach the bottom.

It will fit in later in one of the last steps.

Finishing Before Assembly

This is a good time to finish the inside of the

sides as they will be hard to reach later. First, use wood

filler to hide the heads of the screws. Start by filling it in

with a putty knife and letting it dry:

Wood filler drying

in screw holes:

Then, sand off the excess filler, and sand all edges

smooth. Apply polyurethane to the cleats at this time because

it will be much harder once everything is assembled.

Back and Bottom:

You can now attach the two sides together. The

bottom is attached to side A and should slide in between the blocks

and the lower cleat on side B. Do not attach the bottom to

side B yet.

Front view:

The next step is to attach the back. Make sure

the back fits perfectly. Since side B is not yet attached, you

should be able to move everything around to fit. Do not drill

all the holes at once. Drill one hole at a time and put

in a screw before going on to the next hole. This will give

you the opportunity to get everything lined up incrementally.

Use three screws to attach each side to the back, and four screws to

attach the bottom to the back as shown below:

Approximate screw

locations on the back panel:

Measure carefully so that your holes do not poke

through the other side. Use the longer 2 1/2" screws to

make sure the back is attached securely. Once the back is on, your foot rest is completely put

together!

Side B is still not attached to the bottom.

They are both attached to the back panel, so nothing needs to be

done from the back, but you should hammer in a finishing nail from

the outside of the box through panel B into the bottom panel.

Use a nail set to force the head of the nail below the surface of

the wood, and fill with wood filler.

Top view:

Finishing

Sand the entire project to smooth out the

edges. Sand all surfaces so that the polyurethane will adhere

and make a nice smooth surface. Spray on the polyurethane and

allow to dry. Sand again with a fine grit sand paper and put

on a second coat of poly for a smooth finish.

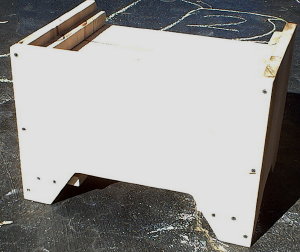

Completed foot

rest:

|